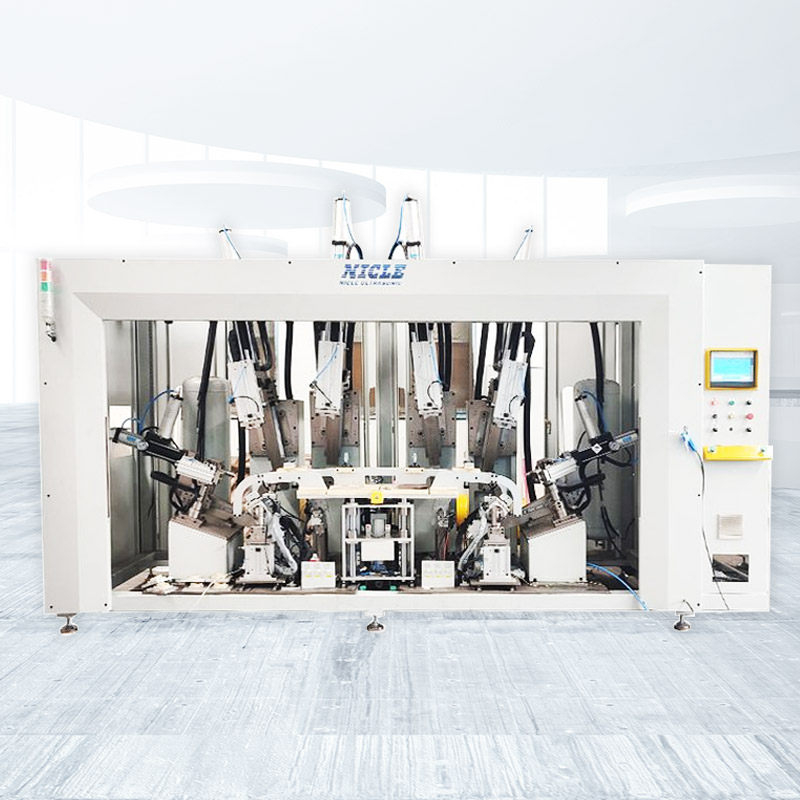

Automotive Interior Parts Automatic Ultrasonic Welding Machine

NC Auto Ultrasonic Welder Series

● Adjustable Welding Units:

Each unit features a buffer stop and 360-degree positioning, allowing operators to adjust individual welding head settings for optimal performance across materials.

● Independent System Design:

The auto ultrasonic welding machine's single-system design simplifies operation and increases efficiency, ensuring reliable performance with minimal maintenance through streamlined component integration.

● Individual Head Angle Adjustment:

Micrometer-precise welding head angle controls ensure optimal surface contact and energy transfer for complex shapes.

● Workpiece Detection and Alarming:

Built-in sensors track workpiece position and alignment. The system immediately warns operators of placement errors or missing parts to ensure quality and prevent damage.

● Fast and Efficient Welding:

The automatic ultrasonic plastic welding system combines high-speed welding with precise control. Continuous monitoring and adaptive controls maintain consistent quality throughout production, maximizing output while ensuring strong welds.

Request for Quote- Features |

- Certification |

- Copperation Steps |

- Advantages |

- Packaging |

- Technology |

- Appilications |

- Reviews

Automatic Ultrasonic Plastic Welding Machine Features

These automatic ultrasonic plastic welding machines harness high-frequency vibrational energy, using a welding head to transmit ultrasonic waves to plastic parts' contact surfaces. This process melts and bonds materials together. Unlike traditional thermoplastic welding, this non-contact method eliminates problems such as high-temperature deformation and color inconsistencies while delivering superior precision and speed for efficient production.

The automotive industry employs these automatic ultrasonic plastic welding machines to weld critical components including dashboards, bumpers, car lights, pipeline components, and window motors. In dashboard manufacturing, ultrasonic welding creates precise, durable bonds between housings and electronic components, ensuring reliability under varied driving conditions. For bumpers, where both structural integrity and aesthetics matter, ultrasonic welding provides an ideal solution through its refined finish and excellent sealing.

The auto ultrasonic welders' eco-friendly and energy-efficient features align perfectly with the automotive industry's shift toward lightweight, sustainable manufacturing. Beyond environmental benefits, they boost production efficiency, enhance part quality, and reduce costs - ultimately strengthening manufacturers' market position.

We are Internationally Certified

Our automotive interior parts automatic ultrasonic plastic welding machines are certificated with CE,ISO and ROSH. They all meet international standards.

Purchasing Guide: Automatic Ultrasonic Welding Machine

We provide comprehensive automatic ultrasonic plastic welding solutions for automotive interior and exterior parts. Follow these steps to complete the process:

-

STEP 1

Sample Evaluation

Review automotive interior sample requirements and technical specifications.

-

STEP 2

Feasibility Study

Analyze the feasibility of the automatic ultrasonic welding techniques for the specific application.

-

STEP 3

Prototype Development

Create and test prototypes based on the evaluated automotive interior samples.

-

STEP 4

Customer Approval

Present the prototype to gather feedback and secure customer approval.

-

STEP 5

Quotation

Issue a detailed quotation for the selected automatic ultrasonic plastic welding machine.

-

STEP 6

Order Confirmation

Finalize the order and confirm all specifications.

-

STEP 7

Manufacturing Process

Manufacture the auto plastic welding machine according to the confirmed order details.

-

STEP 8

Quality Assurance

Conduct thorough quality checks to ensure the auto plastic welding machine meets all standards.

-

STEP 9

Delivery and Installation

Deliver the auto plastic welding machine and complete installation at the customer's site.

-

STEP 10

Training and Support

Provide training and ongoing support to ensure smooth operation of the auto welding equipment.

Custom Dizo Automatic Ultrasonic Welding Machine Advantages

Custom Solution

Solutions customized to your specific needs, supported by 21 engineers ready to assist anytime.

Save Your Time

Full project oversight from initial requirements to final delivery, ensuring efficiency and time savings.

Guaranteed Quality Assurance

Adheres to ISO standards for consistent and reliable quality throughout the automatic plastic welding process.

Professional Service Team

A professional 20-person service team ensures seamless auto plastic ultrasonic welder installation and complete customer satisfaction.

Packaging for Automatic Ultrasonic Plastic Welding Machines

Plastic Welding Techniques in the Automotive Industry

Different welding applications demand specific approaches. Automotive companies often require a blend of automatic ultrasonic welding systems, hot plate welders, vibration welding machines, and hybrid solutions.

We specialize in integrating automated ultrasonic welding into automotive assembly lines, enhancing both efficiency and product quality.

Custom-designed ultrasonic sonotrodes and precise positioning allow us to tackle complex tasks, such as welding large instrument clusters, resulting in superior surface finishes and precise gap control.

Ask for Quote Now

Automotive Plastic Components Welding Applications

We provide specialized auto plastic welding solutions for automotive components that meet all production requirements.

Customer Reviews

Quote Now

Quote Now